Call Us

+86-15626009960

Email Us

yanchunchen@shijiepackaging.com

-

English

-

Español

-

Português

-

Русский

-

Français

-

日本語

-

Deutsch

-

Tiếng Việt

-

Italiano

-

Nederlands

-

ไทย

-

Polski

-

한국어

-

Svenska

-

Magyar

-

Bahasa Melayu

-

বাংলা

-

Dansk

-

Suomi

-

हिन्दी

-

Filipino

-

Türkçe

-

Gaeilge

-

العربية

-

Bahasa Indonesia

-

Norsk

-

اردو

-

Čeština

-

Ελληνικά

-

Українська

-

Basa Jawa

-

فارسی

-

தமிழ்

-

తెలుగు

-

नेपाली

-

မြန်မာ

-

Български

-

ລາວ

-

Latina

-

Қазақша

-

Euskera

-

Azərbaycan

-

Slovenčina

-

Македонски

-

Lietuvių

-

Eesti

-

Română

-

Slovenščina

Home

>

News

>

Industry News

>

Vacuum Negative Pressure Or Piston Drive? How Does The Disinfecting Gel Pump'heart 'work?

Vacuum Negative Pressure Or Piston Drive? How Does The Disinfecting Gel Pump'heart 'work?

2026/01/26

Two Kinds of Driving "Heart": Vacuum Negative Pressure and Piston Driving Mechanism

To understand how the Disinfectant Gel Pump works, we first need to explore its internal driving forces. At present, the mainstream technology path mainly revolves around two core principles, which together determine the suction efficiency, output accuracy and long-term reliability of the pump.

Vacuum Negative Pressure Drive: Ingenious Balance with "Suction" as the Core

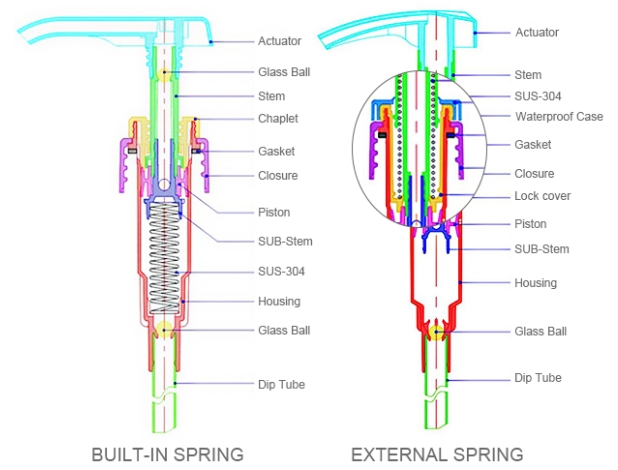

The vacuum negative pressure type, often referred to as the "atmospheric pressure type," imitates the working principle of the classical burette. Its core is to create a local vacuum environment that can change periodically. When the user presses the pump head, a piston or diaphragm connected to the suction tube inside is lifted, which instantly increases the volume inside the pump chamber, thus forming a negative pressure (vacuum). At this time, the external atmospheric pressure is higher than pressure on the liquid level in the bottle, and this pressure difference forces the disinfectant gel in the bottle to be "pressed" into the rising pump cavity through the suction tube to complete the suction process. When the user releases his hand, the spring (or other reset mechanism) pushes the piston down to push the gel in the pump chamber to the outlet through a one-way valve, while the other one-way valve prevents the liquid from flowing back, thus realizing quantitative discharge.

Advantages: The structure is relatively classic, and it has certain advantages in the initial absorption of high viscosity liquid, especially when there is a lot of liquid in the bottle.

Challenge: Its performance is highly dependent on the airtightness of the system. Any small leakage will destroy the vacuum degree and lead to the failure of "not sucking up". For disinfectant gels that are volatile or contain alcohol, prolonged standing may cause a change in the air pressure in the bottle, affecting the efficiency of the first press or the last liquid withdrawal (i.e., the "withdrawal rate").

Piston-driven drive: stable output dominated by "thrust"

Piston-driven is a more direct and robust mechanical propulsion. Its core is a piston reciprocating in a precision cylinder. When the user presses the pump head, the action is transmitted to the piston, either directly or through a lever mechanism, causing it to advance forward in the cylinder, positively squeezing the gel that has been sucked into the cylinder in the previous cycle, forcing it out through the outlet channel. When the user releases the hand, the spring pushes the piston to reset and return, and in the process of the piston retreating, the volume in the cylinder body is increased to generate suction force, and the new gel in the bottle is sucked through the liquid inlet valve to prepare for the next pressing.

Advantages: The output force is direct and strong, less affected by the changes of liquid level and air pressure in the bottle, the output is very stable, the extraction rate is very high, and almost the last drop of gel can be used. Its working mode is more similar to that of a syringe, providing extremely high metering accuracy and reliability.

Challenge: The fitting precision between the piston and the cylinder block and the wear resistance of the seals are extremely high, and more precise manufacturing processes are needed to ensure the smoothness and sealing of long-term use.

In the design of modern high-standard Disinfectant Gel Pump , the two principles are often optimized and integrated. For example, the use of piston drive ensures stable and precise liquid discharge, while the design of the inlet valve is optimized to ensure smooth suction. But no matter how the underlying principles evolve, the ultimate goal of all designs is to point to three cores: precise quantitative output, absolute hygiene and safety, and durable and reliable performance.

Transcendence Principle: Three Innovative Designs for Constructing Safety Defense Line

Understanding how the driving "heart" beats, we also need to examine how a top-notch Disinfectant Gel Pump can build a stronger security and experience defense line in detail.

1. External Spring Design: Completely Eliminate the "Original Sin" of Pollution

The most criticized health hazard of traditional pump head is that its internal return spring is immersed in liquid for a long time. The metal spring is in direct contact with the disinfection gel with complex chemical composition, which has the potential risk of electrochemical corrosion, and may produce trace metal ions or rust impurities that will contaminate the gel itself, which runs counter to the "purity" and "safety" pursued by disinfection products. The revolutionary solution is an external spring design. This design places the spring completely outside the liquid gel flow channel system, in a separate, dry physical space. This means that the spring assumes only the mechanical return function, achieving a physically absolute quarantine with the contents. This fundamental change has eliminated the risk of secondary pollution caused by corrosion of metal parts from the source, making Disinfectant Gel Pump itself a model of health and safety, especially in line with the needs of high-standard health scenarios such as medical, laboratory and food processing.

2. Precise measurement system: scientific and quantitative health discipline

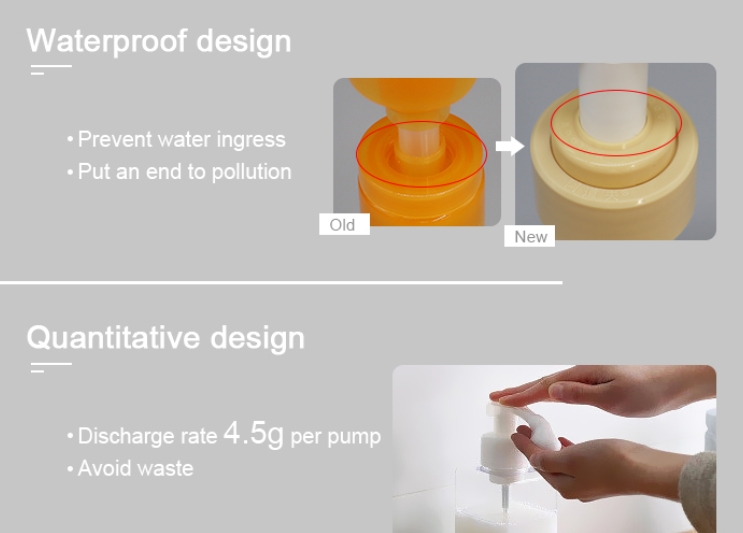

Effective disinfection depends on adequate and uniform coverage. Too much gel causes waste and stickiness, and too little gel can not achieve disinfection effect. Therefore, accurate quantification is one of the core values of Disinfectant Gel Pump . Advanced pump heads offer scientifically calibrated dosing options such as Model 02 (4.5 ± 0.5ml) and Model 202 (2.5 ± 0.25ml). This metering accuracy, to ± 0.25 ml, is usually guaranteed by a precisely designed piston stroke volume or chamber volume. It ensures that each compression provides an adequate amount that is strictly in line with public health recommendations, making scientific disinfection a repeatable and verifiable daily behavior, while also facilitating material consumption management and cost control for institutions.

3. Multiple leak-proof sealing and humanized interaction

When not in use, it is important to keep the outlet clean to prevent spontaneous leakage or evaporation of the gel. This relies on a leak-proof seal design. High-end pump heads usually incorporate precision shut-off valves (such as umbrella valves or ball valves) that close the flow passage instantaneously after the end of the compression. The combination of a double leak-proof mechanism, such as the screw-on seal of the outer cap working in conjunction with an internal elastomeric seal, ensures that the gel is effectively locked in, keeping the bottle and the environment clean, even if the product is turned upside down, transported, or subjected to temperature changes.

In addition, humanized operation is directly related to compliance. The clear directional arrow and finger-shaped ergonomic pressing surface design guide the user to carry out intuitive and labor-saving one-handed operation, ensuring that the gel can be obtained quickly and accurately in any emergency or daily situation to enhance the use experience.

The Foundation of Green and Safety: Materials and Certification

A trustworthy Disinfectant Gel Pump , its material itself is the promise of safety. The main components of the pump body are made of pure polypropylene (PP) material, which is not only chemically stable, compatible with most disinfectant gel formulations, non-toxic and tasteless, but also completely recyclable, in line with the concept of green environmental protection. More importantly, the whole product components are tested and certified according to strict international safety standards (such as FDA, LFGB, REACH, etc.), and a comprehensive safety compliance system is built from the source of materials to the output of finished products, which is suitable for a wide range of disinfection application scenarios from medical institutions to families.

To choose a pump head is to choose a complete hygienic solution.

Therefore, when we ask "vacuum negative pressure or piston drive", what we really explore is how a Disinfectant Gel Pump can solve the complex proposition of precision, safety, reliability and environmental protection with the best engineering scheme. The driving principle is its "heart", which determines its basic performance and reliability; the external spring design is its "immune system", which safeguards the absolute purity of the content; the precise measurement is its "autonomic nerve", which ensures the scientific and effective behavior; the leak-proof sealing and humanized design are its "friendly interface", which ensures the smooth experience and clean environment.

Choosing an excellent Disinfectant Gel Pump is far more than choosing a packaging accessory. It is the faithful executor of the efficacy of your disinfection products, the physical witness of the brand's commitment to consumer safety, and the key contact point to enhance the experience of public and personal hygiene habits. Under the guarantee of invisible precision mechanical movement and visible safety materials, every precise and clean pressing is silently strengthening the health defense line that we rely on together. This is the far-reaching value of an excellent "pump core".