Call Us

+86-15626009960

Email Us

yanchunchen@shijiepackaging.com

-

English

-

Español

-

Português

-

Русский

-

Français

-

日本語

-

Deutsch

-

Tiếng Việt

-

Italiano

-

Nederlands

-

ไทย

-

Polski

-

한국어

-

Svenska

-

Magyar

-

Bahasa Melayu

-

বাংলা

-

Dansk

-

Suomi

-

हिन्दी

-

Filipino

-

Türkçe

-

Gaeilge

-

العربية

-

Bahasa Indonesia

-

Norsk

-

اردو

-

Čeština

-

Ελληνικά

-

Українська

-

Basa Jawa

-

فارسی

-

தமிழ்

-

తెలుగు

-

नेपाली

-

မြန်မာ

-

Български

-

ລາວ

-

Latina

-

Қазақша

-

Euskera

-

Azərbaycan

-

Slovenčina

-

Македонски

-

Lietuvių

-

Eesti

-

Română

-

Slovenščina

Home

>

News

>

Industry News

>

Full Analysis Of The Interior Of The Pump Head From Pressing To Discharging!

Full Analysis Of The Interior Of The Pump Head From Pressing To Discharging!

2026/01/26

It all starts with the downward pressure of your fingertips. This manpower is taken up by the ergonomic press panel at the top of the pump head. The clear directional arrow on the panel not only provides visual guidance, but also effectively directs the applied force to the core motion direction of the internal drive structure through its curved surface design. The pressure is transferred down through the central linkage or piston rod and becomes the initial kinetic energy that starts the cycle of the entire system.

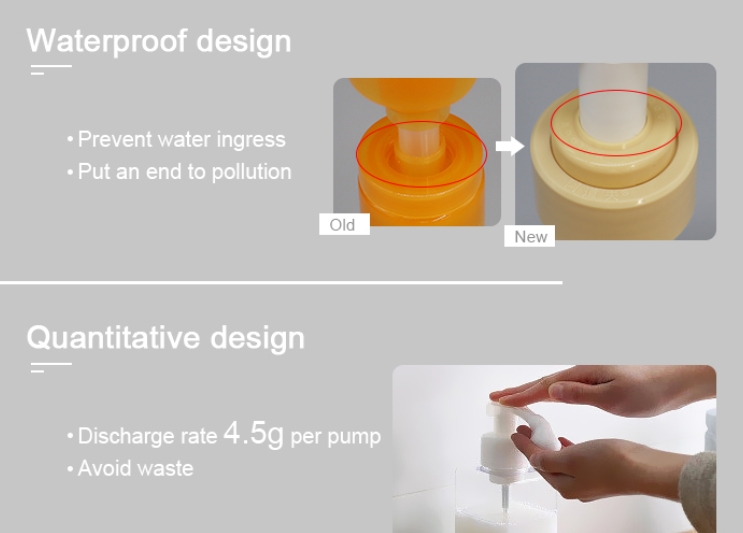

In this process, a key player comes into play: the spring. In traditional pump head designs, the return spring is usually placed in the liquid flow channel and is immersed in the product for a long time. However, the advanced Shampoo Lotion Pump we are focusing on use a revolutionary outboard spring design. The spring is strategically placed in a completely separate and dry compartment outside the pump chamber. When you press down, the spring is compressed and stores elastic potential energy; when you let go, it is this stored energy that precisely pushes the pressing head back to the initial position, ready for the next suction. The revolutionary significance of this design is that it completely blocks the contact between spring metal and any chemical formula such as shampoo and shower gel, fundamentally eliminates the risk of product contamination caused by metal corrosion (rust), and improves the safety of packaging components to a new level.

The Precise Dance of Fluids — — Aspiration, Metering and Drainage Cycle

As the piston rod descends, a precise fluid circulation occurs inside the pump in three stages:

The first stage: drainage and accurate measurement

The downward pressure of the piston rod directly drives a precision-formed piston to move downward in a closely matched pump cylinder. The piston is equipped with a special seal ring (usually rubber or elastomer material) to ensure a tight fit with the inner wall of the pump cylinder. The downward movement of the piston compresses the volume of the pump chamber at its front end. The metered quantity of liquid already present in this chamber (that is, aspirated in the previous cycle) has nowhere to go, and the only way out is to open the one-way drain valve (usually a small ball, umbrella valve, or membrane valve) located on the outlet channel. The liquid is pushed steadily under pressure, through the mouth of the pump head, and finally falls into your palm. The volume of liquid discharged is precisely the fixed volume strictly defined by the piston stroke and the inner diameter of the pump cylinder, which is the physical basis for the precise measurement of Shampoo Lotion Pump . For example, the Model 02 is designed to deliver 4.5 ± 0.5ml with specific structural parameters, while the Model 202 is designed for a smaller dose requirement of 2.5 ± 0.25 ml. The accuracy of this mechanical volumetric metering method is much higher than that of the traditional method relying on air pressure or fluid viscosity, which ensures that no matter how high or low the liquid level in the bottle and how small the viscosity of the product changes, each press will give almost the same amount.

The second stage: reset and vacuum suction

When your finger is released, the compressed outer spring releases its energy, pushing the piston rod and piston back up. The upward movement of the piston recreates a gradually increasing space in the front of the cylinder. This space is not vacuum, but the instantaneous reduction of pressure forms a certain negative pressure (vacuum degree) in the pump chamber. At this time, the liquid inlet check valve at the bottom of the suction tube (to prevent backflow of liquid) is pushed open under the pressure difference between the atmospheric pressure in the bottle and the negative pressure in the pump cavity. The shampoo or shower gel in the bottle is sucked into the expanding pump cavity through the suction tube under the impetus of atmospheric pressure until it is full. At this point, a complete "drain-suction" cycle is ready for the next press command.

The third stage: the protection of quietness — — leakage prevention and sealing

The end of the cycle does not mean end of the system. In the non-use state, how to ensure that the products in the bottle do not leak, dry up or be contaminated is another key to measure the reliability of the Shampoo Lotion Pump . This relies on a multi-seal leak-proof design:

Immediate closing of the liquid discharge valve: at the moment when the piston is reset and the liquid discharge action stops, the one-way liquid discharge valve at the outlet quickly returns under the action of its own elasticity or gravity to tightly seal the outlet channel. This effectively prevents the phenomenon of "spitting milk" or dripping caused by the change of pressure in the bottle or the gravity of the product itself, and keeps the bottle mouth and body clean for a long time.

Screw lock seal: The pump head is usually equipped with a screwable cover. When the cap is tight, it engages the pump body with a precision screw structure and compresses the internal elastic sealing gasket to form a solid physical barrier. This barrier can not only prevent accidental leakage of liquid, but also block the entry of air, slow down the speed of oxidation, volatilization or contamination of products, and is essential to maintain the stability of active ingredients in shampoo and shower gel and prolong the shelf life of products after opening.

Material barrier: The whole pump body, including piston, cylinder, valve, etc., is made of non-toxic materials (such as high-quality PP polypropylene) that meet international safety standards. These materials are not only chemically stable and compatible with personal care formulations, but their precision machining also ensures long-term sealing of component joints.

Building the systematic advantages of excellent experience

By deconstructing the inner workings, we can systematically understand the all-round advantages of a good Shampoo Lotion Pump :

1.The Cornerstone of Health and Safety: External Spring and Safety Material

The external spring design is a fundamental innovation in health and safety, which solves the inherent defects of traditional pump heads. With the environment-friendly recyclable PP material used in the whole link and the international safety certification, it ensures the safety from the packaging components themselves to the contact with the contents, so that consumers can rest assured.

2.Balance between efficiency and economy: accurate measurement

The precise output of 4.5 ± 0.5ml or 2.5 ± 0.25ml means that consumers can get the best single dosage set at the time of product development-enough to produce rich foam or achieve nursing effect, and avoid unnecessary waste. For brands, this helps to build a consistent product experience and achieve more accurate cost control and market forecasting.

3.Unity of reliability and convenience: leak-proof design and user-friendly operation

The leak-proof valve and the spiral seal jointly construct leak-proof double insurance, which ensures the neatness and stability of the product in transportation, storage and daily use. Clear direction arrows and ergonomic pressing head design make every use intuitive, labor-saving and smooth, even in wet and slippery bathing environment, it can be easily operated, which significantly improves the user's pleasure and product compliance.

4.Broad compatibility and environmental responsibility

Thanks to their stable mechanical principles and material properties, these Shampoo Lotion Pump are highly compatible with product formulations and can adapt to liquids of different viscosities, ranging from thin emulsions to viscous shampoos. At the same time, it mainly uses recyclable and biodegradable PP materials, which reflects the brand's commitment to sustainable development and conforms to the growing global concept of environmental protection consumption.

Tiny parts, grand experience

From a gentle press to a precise liquid, the interior of the Shampoo Lotion Pump has completed a precise journey that combines mechanics, materials and design wisdom. It is not only a tool to use products, but also a guardian of product quality, a medium to convey brand ingenuity and a key to enhance the sense of daily ritual.

Choosing a Shampoo Lotion Pump with advanced technology and sophisticated design means that your personal care products are equipped with a reliable, accurate and safe "heart". It ensures that every interaction with consumers is a perfect fulfillment of its promise-precise, clean, convenient and reassuring. Between the micro mechanical rhythm and the macro excellent experience, it is these evolving precision pump head technologies that silently define the quality standards of modern personal care products and the upper limit of user experience.